I was recently gifted several packs of used vintage photo paper. As usual, the condition of which can only be assessed by its use due to unknown storage conditions.

There was a mix of B&W and colour papers, mostly kodak and Agfa.

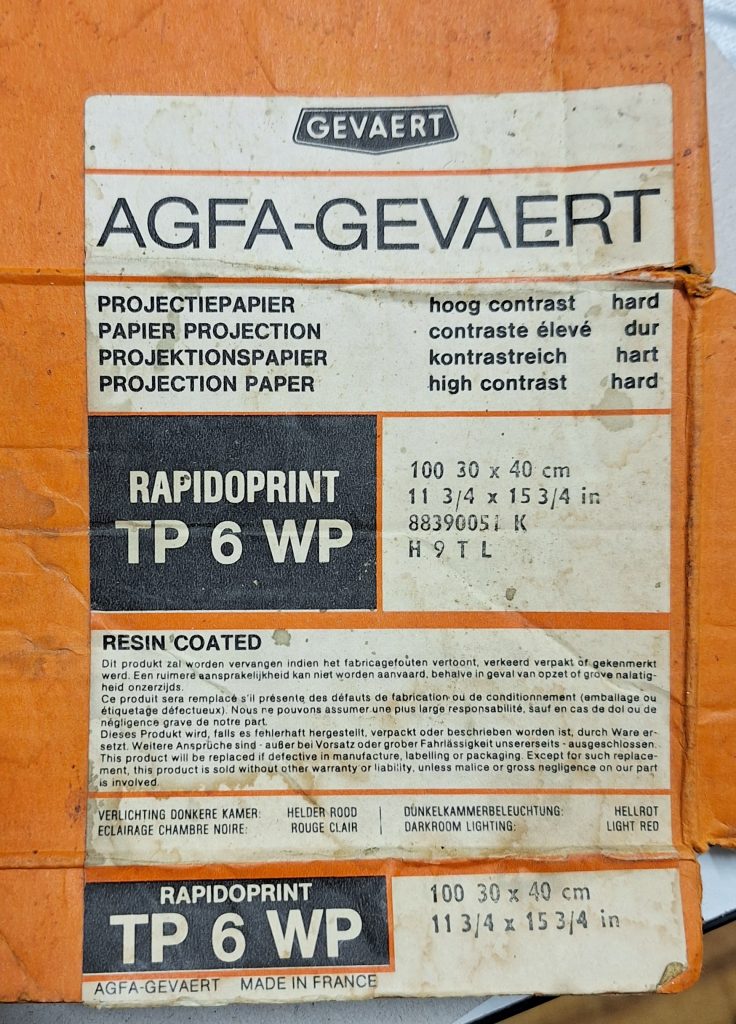

Today, I did some tests on the Kodak Veribrom and an unusual Agfa Gevaert Rapidoprint, which I’d never heard of before.

The Kodak Veribrom is in a variety of sizes and finish.

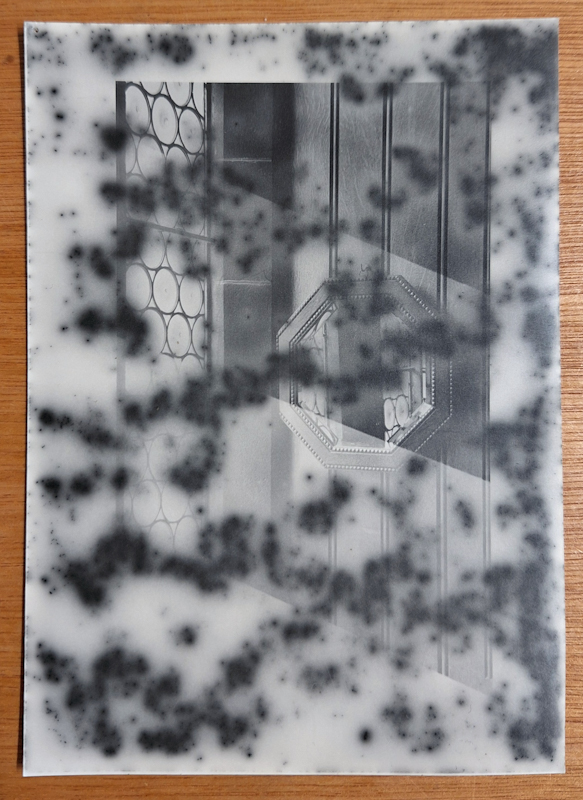

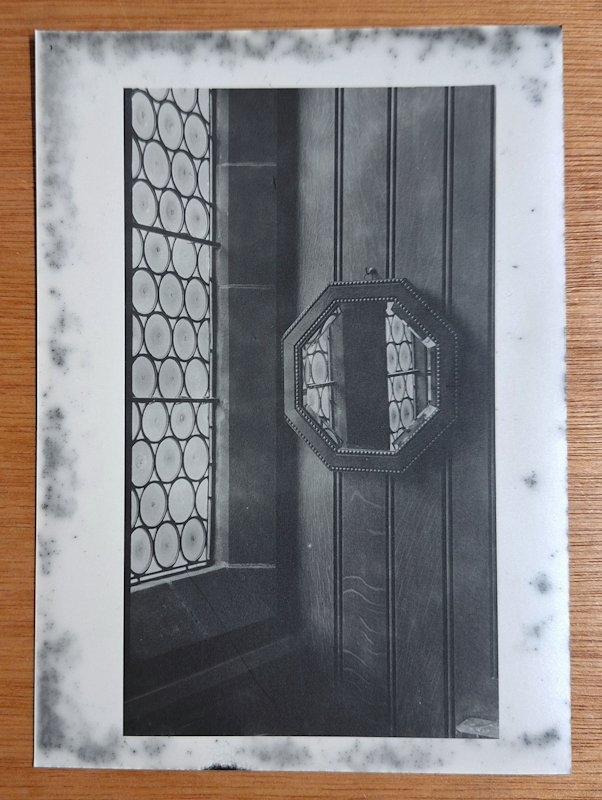

All packs displayed mottling of the emulsion on processing. Top sheets in the pack were affected the most, less so with later sheets, where it appeared mostly around the perimeter of the paper.

Although I quite like the finish and I don’t mind the mottling around the edges.

There was also a variation of colour base with the paper between white and a warm cream.

The Agfa Gevaert Rapidoprint TP 6 WP was a surprise, as I’d never heard of it, and I’d already processed a few before looking online for details. This pack is 12×15 inch, I’ll have to double-check.

It turns out it’s a paper for graphics art and prints in a very short time. Hence, the name Rapidoprint

The paper is very lightweight and has developer chems embedded into it, processed in a strong alkali solution, and then washed. Producing a short life print, although a fixer can be used to prolong it.

Online, it says it should be extremely high contrast, but that’s not what I found. I’m not sure if that’s down to fogging, deterioration or if this is another variety with a fuller tonal range. There’s not a lot of info available online.

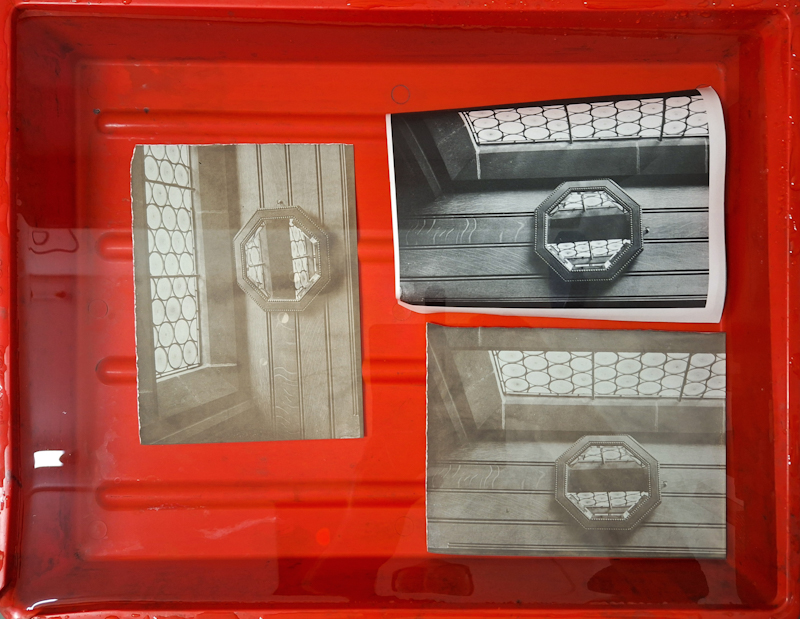

Here it is in the wash with a gloss Kodak Veribrom. You can see the difference in tone and contrast. The Agfa being much warmer and flatter. Which I actually really like.

Although online recommendations are to use an alkali activator with the embedded paper developer, I had developed with Ilford PQ Universal additionally and was instantly taken by surprise by the speed of development, around 20 seconds for my exposure times. If there was enough of this paper, I’d do a few more experiments with wxposure to pricessing times to final tone/cobtrast. Sadly, there are only ten more 12×15? inch sheets.

There’s something about the bromide and this Agfa paper that feels really good in hand. The Agfa being so lightweight and flimsy when wet and then there’s that tone when dry. The kodak Varibrom also had qualities of its own. The gloss looks like a nightmare to dry flat.

I’ll keep my eye open for more of the Agfa Rapidoprint in future.

Rapidoprint is developer incorporated, in an Activator.Stabiliser processor a damp print would emerge in around 15 to 20 seconds.

I have the data-osheetfor the Ilfoprint papers, which was essentially the equivalent and it states the emulsion contains Hydroquinone. The activator was essentially Sodium Hydroxide based, the Stabiliser was Sodium Thiocyanate based. There was no wash, print stability required dry cool storage. Ilford recommended fixing for complete permanence.

When our two local newspapers merged I was given an Ilfoprint processor vand various other items from the closed darkroom. Early Ilfospeed was developer incorporated and I tried the machine with Ilfoprint Activator, but the results were not quite right, so I mixed my own Activator and the results were perfect.

Excellent Info Ian, thank you.