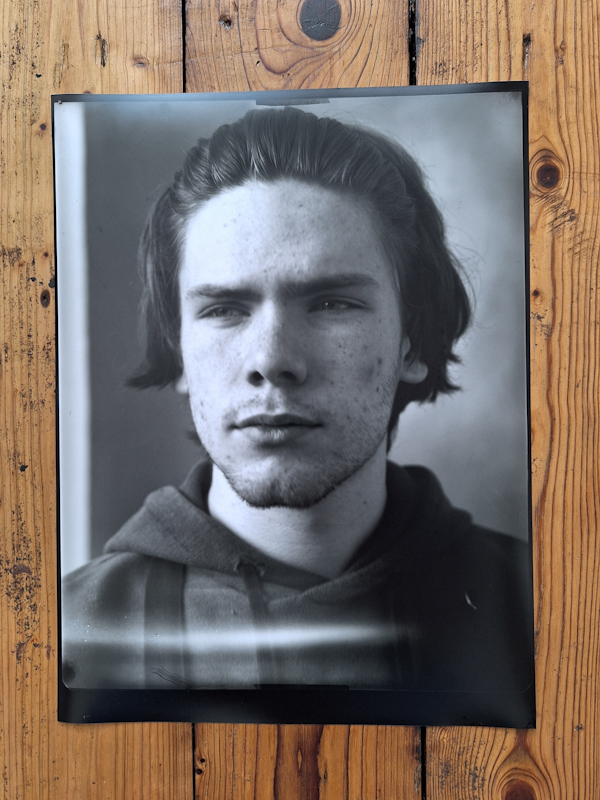

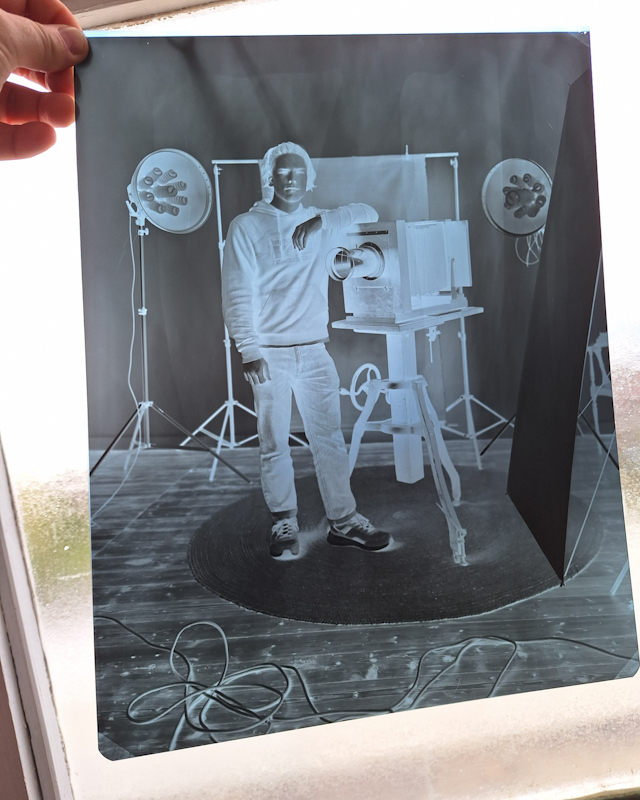

Ishmael is a second year Photography student, who has been on work placement with us at The John Rylands Research Institute and Library for the past week. He’s also doing a couple of days at my studio looking at various analogue processes.

I was keen for him to look at various processes he could use in his home made cnc’d camera.

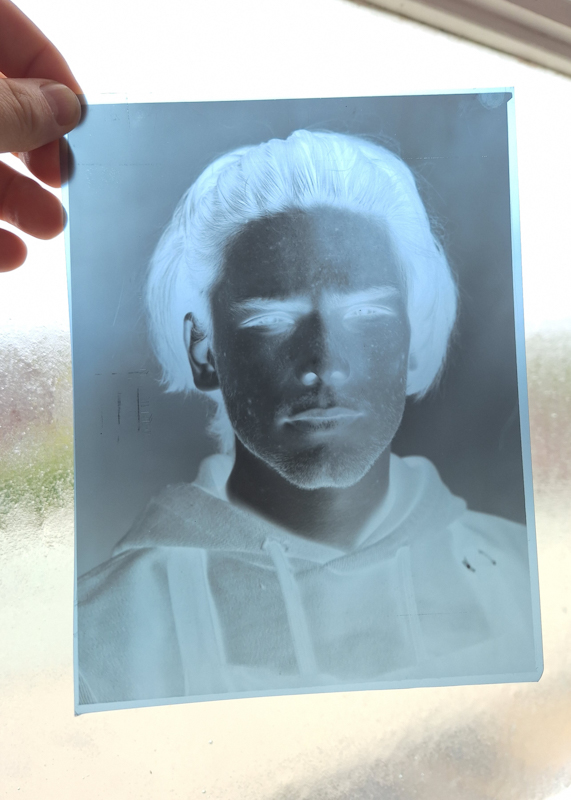

Today we looked more closely at the Agfa Xray film I recently purchased. Moving up from 1/2 plate to whole plate.

First thing we noticed, the bigger the negative, the more likely you are to scratch the emulsion.

Again it was a bright day and no mechanical shutter resulted in us stopping lenses down to F32 – F18, exosures 1 – 6 seconds.

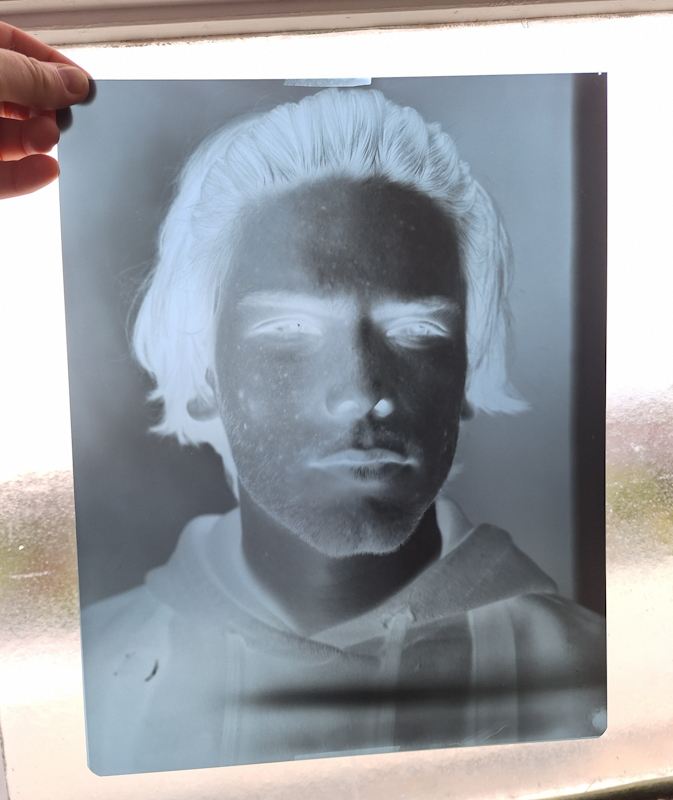

We then moved up to 12×15 inches, which required just trimming a little off the length with a sharp blade.

Discovered that 30cm is not 12 inches, I’d always assumed it was, and never thought to check. So we taped the film to a sheet of 12×15 inch glass to prevent it warping in the extra large wooden plate holder. The smaller plate holders all have metal inserts for film.

Always use a tray that the negative will fit into. Although my trays say 12×16 inch, they are smaller at the base than the top! So a couple of negs have development marks from insufficient and awkward coverage.

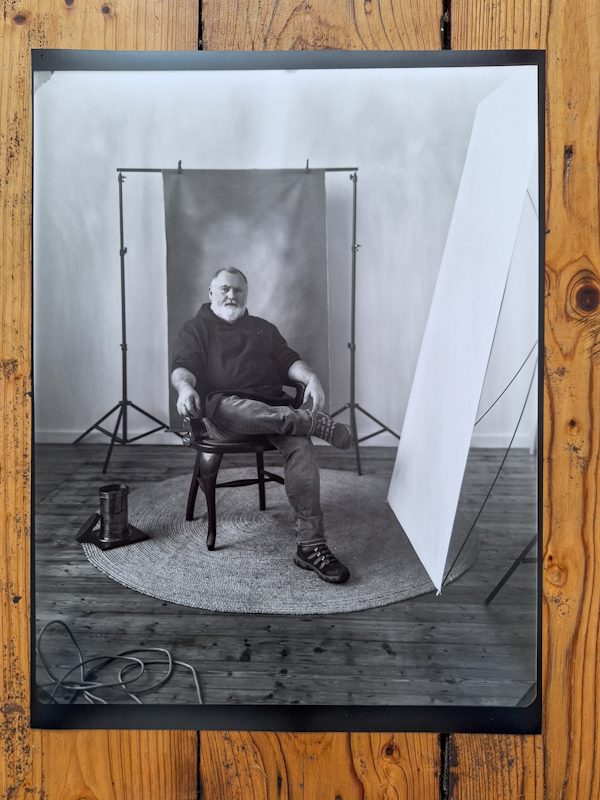

Quickly contact printed onto Ilford MGRC Warmtone paper. F4.5 for 45 seconds Grade 1.

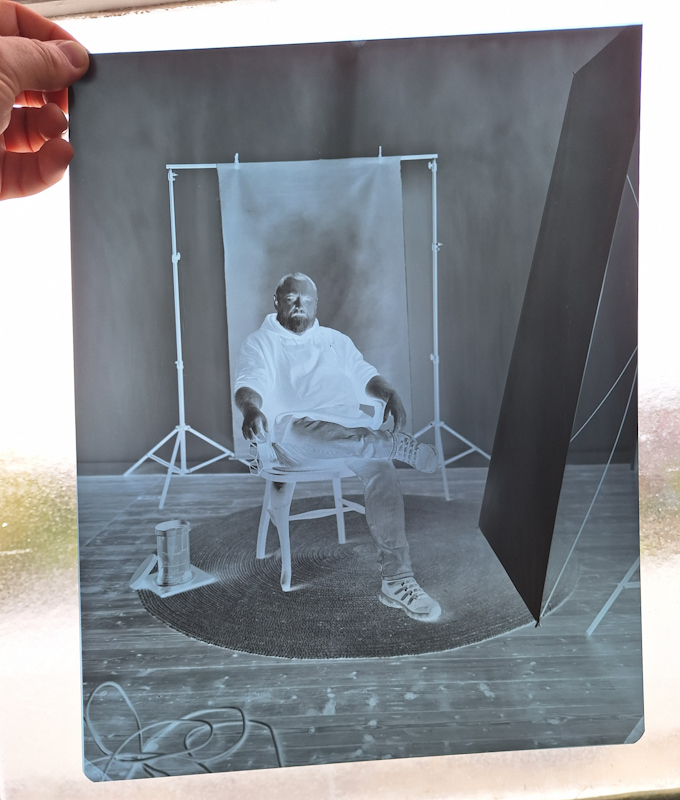

Ishmael then cut a dozen or so 12×18 cm smaller sheets to take home with him to try in his own camera. I look forward to seeing his results.

This was a good test for full sheet sizes, as I need to make some copy negs for Bromoil printing for an exhibition in June.

So, today we learnt the emulsion is at risk of scratching, as documented online. Hesitation can easily lead to development lines, so maybe further dilution of the developer is needed. Oh and use a processing dish big enough to accommodate the negative. Rookie error by me. And the affordable nature of xray film means you are not reluctant to try a few extra sheets to experiment.